Creating a concentric bowl is a challenge. One I have to play with to master. You can see from the bottom picture the when I was trying to remove the inner circle, a crack formed to the outer edge. I've got some ideas on how to work around this.

First, I could sacrifice the glass at the center and possibly make a number of cuts through the middle, hoping to get enough play to release it. Second, I could drill a small hole in the center before making my cut and try to score to that.

Third, I could cut 2 distinct half circles for the outer edge, thereby having a consistent cut, but the lines will still be visible in the final piece. I believe that the project will look even better when there is not a visible line in the edge piece, so I will aim for that in future pieces.

The other challenge to the plate was the inner circle. I cut it the same diameter as the inner piece. This require a bit more grinding than I would have liked to done and left some small gaps. They can't be seen now, but in the future, I will slightly shrink the inner circle next time.

Friday, December 23, 2011

Sunday, November 13, 2011

Basket weave plate

I'm trying my hand at a basket weave. This one is a simple layer on layer with spaces in between built in. I've tried .5 inch strips with .5 inch chips to fill in between on the ends. To make it work out, the end chips are .25 by .5 inch, all other chips are square.

I can't wait to see how this one turns out.

UPDATE: It turned out wonderfully! nice round circles inside with negative space. This is a very cool project that I'm sure I will need to do again and again.

Tuesday, November 1, 2011

Layered Pattern Final

The layered plate is finished, for now. I am not happy with the edge on one side of the plate. If you noticed from the previous post there was some hangover that I should have trimmed before fusing. Call it laziness, call it low blood sugar, but in the end I had to do something about that edge. So I ground away the part that I didn't want and then slumped it. I figured that it would also fire polish my grinding away. Well it did, to a certain extent, but not enough for my taste. It was glossy but not rounded. My mistake was that to properly fire polish. it should be done while flat and at much higher temperatures than a slump.So next time around it is full fuse, cold working (if needed), fire polishing (if needed), then slumping. I am going to ask at my local store about doing a fire polish and then re-slumping. My fear is that re-slumping it will have it deform. I will post an update with a final decision, once I know.

I hope you like the plate, I know I do, even with the lessons learned. Remember everything is an experiment.

I hope you like the plate, I know I do, even with the lessons learned. Remember everything is an experiment.

Sunday, October 30, 2011

layered pattern

I am attempting to do a layered pattern here as an experiment. I can see during my assembly that I'm a little bit off from a perfect cut. For now I'm going to do a full fuse and then trim , if needed. I ended up justifying 3 sides, so I will only have to trim 1 side, if at all.

In a geometric project I usually use my Morton cutting system. Today I noticed a bit of give in some areas which made my cuts not as accurate as they should be. So I am considering trying s new system that I've seen around called Beetle bits.

I like the integrated angle edge and the cutter add on. I'll have to let this gel for a while to see if I want to invest in it. I have so many other things I'd like to buy, like a better scroll saw and a glass saw that I can cut glass bricks with.

Can't wait to see how this turns out.

In a geometric project I usually use my Morton cutting system. Today I noticed a bit of give in some areas which made my cuts not as accurate as they should be. So I am considering trying s new system that I've seen around called Beetle bits.

I like the integrated angle edge and the cutter add on. I'll have to let this gel for a while to see if I want to invest in it. I have so many other things I'd like to buy, like a better scroll saw and a glass saw that I can cut glass bricks with.

Can't wait to see how this turns out.

Saturday, August 27, 2011

Simple Bowl

We are going to a house warming party tomorrow. I figured ,what better to give the new house owners than a fused bowl. So I went out and bought a new bowl mold and a circle cutter, both of which I'd been wanting to get but hadn't invested in yet. Found some spectrum 96 glass I liked and fused some clear on top and slumped it into my new mold.

I'm not bothering to include instructions from this point on, unless it is complicated or uses an unusual firing schedule.

I hope they enjoy this!

Saturday, July 2, 2011

Shhh, It's a beach panel!! completed project.

This has been a top secret project!! Well, no one would have been harmed if it had leaked out, but it was for a gift that might have spoiled a surprise.

My wife and I worked on this panel together from concept to fruition. I was concerned the whole time that we were trying techniques we'd never tried and yet had a time line and no time to experiment. We could not mess this up!!!

So my record keeping has suffered, due to our time lines and doing some things on the fly, but this is the general way we did this panel. First, I did a full fuse of the sky blue that had some nice subtle coloring differences in it. Then I cut the palm trees out and we arranged them and laid down multi-colored blue frits and we did a contour fuse. I did it slightly less time and temp than the spectrum schedule. then we laid down our sandy frits and some more of the blue water frit and cloud white frit and did a tack fuse.

We did not like the way the sand came out, too many dark spots. So then we placed some more of the sandy colored frit on and did another tack fuse.

We did not like the way the sand came out, too many dark spots. So then we placed some more of the sandy colored frit on and did another tack fuse.

In between each of these firings I ground down the panel side to be able to fit the stand that we purchased.

Lessons learned form this project. When doing frit on the edge of a panel use some type of dam so that we do not have to try to ground off so much fused frit. Keep better records!! even on time pressure items. Wash cut pieces better! You may not be able to see it, but the leaves have some black lines around the edges that were there for cutting, but I failed to wash off completely. Luckily, in this application, they look nice and add something to the piece. File that one under happy accident.

My wife and I worked on this panel together from concept to fruition. I was concerned the whole time that we were trying techniques we'd never tried and yet had a time line and no time to experiment. We could not mess this up!!!

So my record keeping has suffered, due to our time lines and doing some things on the fly, but this is the general way we did this panel. First, I did a full fuse of the sky blue that had some nice subtle coloring differences in it. Then I cut the palm trees out and we arranged them and laid down multi-colored blue frits and we did a contour fuse. I did it slightly less time and temp than the spectrum schedule. then we laid down our sandy frits and some more of the blue water frit and cloud white frit and did a tack fuse.

We did not like the way the sand came out, too many dark spots. So then we placed some more of the sandy colored frit on and did another tack fuse.

We did not like the way the sand came out, too many dark spots. So then we placed some more of the sandy colored frit on and did another tack fuse.In between each of these firings I ground down the panel side to be able to fit the stand that we purchased.

Lessons learned form this project. When doing frit on the edge of a panel use some type of dam so that we do not have to try to ground off so much fused frit. Keep better records!! even on time pressure items. Wash cut pieces better! You may not be able to see it, but the leaves have some black lines around the edges that were there for cutting, but I failed to wash off completely. Luckily, in this application, they look nice and add something to the piece. File that one under happy accident.

Sunday, June 19, 2011

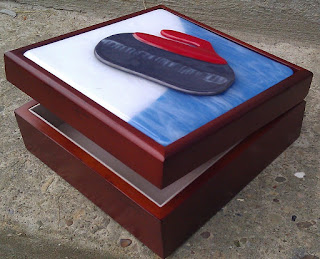

Curling Tile Jewelry box project - Finished

Well here you have it!The finished curling jewelery box. I'm extremely happy with the way this turned out, so much so that I am going to make another tile to use in something for myself. The tack fuse came off just fine.

Happy Day!

Happy Day!

Wednesday, June 15, 2011

Curling Tile Jewelry box project

So for my next project I am making a jewelry box for either a Chinese auction or some such give away at the Pittsburgh Curling Club's Tropicurl event. Essentially, I'm making a tile to place in an inset of a 6" x 6" oak jewelry box.

My first step has been to do a full fuse of the "ice". This time around I am using all Uroboros glass that has a COE of 90. The bottom layer was of a straight blue and whites glasses that I cut arcs in to simulate the house (read, target). I then place a whispy clear and white mixture glass on top. I think this does an excellent job at mimicking how this actually looks. In reality the pattern is painted first then water placed on top and frozen, so you get this kind of muted color with frosty bits on top.I did this with my regular full fuse schedule.

Next I am tacking on a curling stone piece that I had fused a while back when I did a mosaic piece that was part fused glass. I made a bunch of them when I did that project.

Once the tack is done, I will insert it in the box, and of course provide pictures :-).

Tack fuse schedule:

My first step has been to do a full fuse of the "ice". This time around I am using all Uroboros glass that has a COE of 90. The bottom layer was of a straight blue and whites glasses that I cut arcs in to simulate the house (read, target). I then place a whispy clear and white mixture glass on top. I think this does an excellent job at mimicking how this actually looks. In reality the pattern is painted first then water placed on top and frozen, so you get this kind of muted color with frosty bits on top.I did this with my regular full fuse schedule.

Next I am tacking on a curling stone piece that I had fused a while back when I did a mosaic piece that was part fused glass. I made a bunch of them when I did that project.

Once the tack is done, I will insert it in the box, and of course provide pictures :-).

Tack fuse schedule:

Segment | Ramp | Temp | Hold |

1 | 300° | 1150° | 30 |

2 | 400° | 1370° | 0 |

3 | AFAP | 950° | 60 |

4 | 150° | 800° | 10 |

Wednesday, June 8, 2011

Bamboo project part 3

My mantra has been that is it all "an experiment". Well, some experiments go well, others not so much. So far, I would rate this a 6 out of 10. My contour fuse was too hot for too long and ended up being more of a full fuse and less of a contour. This being my first time ever doing a contour fuse, I can't be too upset with it.

My mantra has been that is it all "an experiment". Well, some experiments go well, others not so much. So far, I would rate this a 6 out of 10. My contour fuse was too hot for too long and ended up being more of a full fuse and less of a contour. This being my first time ever doing a contour fuse, I can't be too upset with it.I can however pick on my color choices a bit. I would have liked the leaves to be more opaque. I also would like the bamboo to have a bit more color texture to them. I can partly explain all of this by saying, that is what the glass store had available when I was there. I did not want to go through the bother of ordering glass to get exactly what I wanted. With those things in consideration, it was well worth the time and expense to get the experience.

My next step will be etching the back of the glass. I think I may have settled in on etching the whole back with the exception of the bamboo relief. I will post the finished piece after that.

Tuesday, June 7, 2011

Bamboo project part 2, contour fuse

With the relief image of the bamboo done, I've now laid out colored pieces for bamboo on top. The idea is that I will contour fuse the top pieces into the bottom piece. A contour fuse is mid way between a tack fuse (where the top piece doesn't really sink into the bottom piece but will have softer edges) and a full fuse (where the top piece sinks all the way into the bottom piece).

With the relief image of the bamboo done, I've now laid out colored pieces for bamboo on top. The idea is that I will contour fuse the top pieces into the bottom piece. A contour fuse is mid way between a tack fuse (where the top piece doesn't really sink into the bottom piece but will have softer edges) and a full fuse (where the top piece sinks all the way into the bottom piece).I left the fiber paper attached to the bottom for the moment, I did not want to possibly lose the relief image during the contour fuse cycle. I also cut the glass "freestyle" with no pattern. I am hoping this will give it a more organic feel in the end.

I am very excited for this to work out and very nervous that the contour fuse will be too much or too little. This is my first contour fuse and therefore officially a test of the proper schedule. Here's to crossing my fingers and toes. I can't wait until tonight to see if this worked out!

I'm using the Spectrum glass contour fuse schedule, because I'm using their glass.

- SP 744 Easter Opal

- SF 798 Khaki

- SF Light Green

Segment | Ramp | Temp | Hold |

1 | 300° | 1150° | 30 |

2 | 400° | 1440° | 10 |

3 | AFAP | 950° | 60 |

4 | 150° | 800° | 10 |

Tear drop pendant project Part 2, fusing complete.

The pendants are all now fused. You can see, in the first picture, that all of that frit reduced down to about half. They have some great coloring to them. The next steps for them will be sanding them down a bit with a diamond pad and then fire polishing them. Add a bail and necklace and we will be good to go.The fire polishing schedule is below.

Fire Polishing Schedule

Segment | Ramp | Temp | Hold |

1 | 400° | 1350° | 10 |

2 | AFAP | 960° | 60 |

3 | 150° | 700° |

Monday, June 6, 2011

Tear drop pendant project start

My wife has started her first fused project in the new kiln. She is working on a set of teardrop pendants in a cast mold, something I will be doing later myself. She is using a mix of different frit colors and sizes.

My wife has started her first fused project in the new kiln. She is working on a set of teardrop pendants in a cast mold, something I will be doing later myself. She is using a mix of different frit colors and sizes.- 136-96 Dark Blue medium frit

- Clear medium and fine frits.

- Clear iridized medium frit.

- 5333-96 Deep Aqua fine frit.

- 138-96 Adventurine Blue coarse frit

These are layered in different configurations. and are now being fired with the schedule below. Time for us to watch and wait. Here's hoping for a great experiment!

Segment | Ramp | Temp | Hold |

1 | 600° | 1475° | 30 |

2 | AFAP | 960° | 90 |

3 | 100° | 700° |

Sunday, June 5, 2011

Bamboo project part 1

My wife and I have a number of of projects we are itching to start. First up is a bamboo panel, hopefully for my office. I got this idea from an article I read online about using float glass (glass that doesn't have a tested COE). I however am not that brave and I am using all Spectrum 96 glass in this project.

The idea will be to have a relief bamboo picture in the back and a tack or contour fuse of some colored bamboo on the top. I am also considering using some Armour Etch on the back to either frost sections of the back, or the whole back, but this all depends on how everything turns out. Remember, It's all an experiment after all.

So to start out this project, I've taken 1/8" fiber paper and cut some bamboo stem sections, leaves and shoots. I've arranged them on some thin fire paper on the kiln shelf. I've taken 2 layers of clear spectrum glass and placed them on top. 7" by 9" if your curious. I am performing a full fuse to make the impression on the back of the panel and to make sure that the 2 layers of glass combine. I am using the Spectrum recommended schedule for a full fuse, as I did for my first full fuse test.

Other project in the queue: Teardrop necklace cast, Hexagon bowl, and a beach scene panel.

The idea will be to have a relief bamboo picture in the back and a tack or contour fuse of some colored bamboo on the top. I am also considering using some Armour Etch on the back to either frost sections of the back, or the whole back, but this all depends on how everything turns out. Remember, It's all an experiment after all.

So to start out this project, I've taken 1/8" fiber paper and cut some bamboo stem sections, leaves and shoots. I've arranged them on some thin fire paper on the kiln shelf. I've taken 2 layers of clear spectrum glass and placed them on top. 7" by 9" if your curious. I am performing a full fuse to make the impression on the back of the panel and to make sure that the 2 layers of glass combine. I am using the Spectrum recommended schedule for a full fuse, as I did for my first full fuse test.

Segment | Ramp | Temp | Hold |

1 | 300° | 1150° | 30 |

2 | 400° | 1475° | 10 |

3 | AFAP | 950° | 60 |

4 | 150° | 800° | 10 |

Other project in the queue: Teardrop necklace cast, Hexagon bowl, and a beach scene panel.

Monday, May 30, 2011

Slump test 1 done!!

I'm very thankful for my success so far. I seem to have received very good advice to this stage and have had no real problems. I did have some misgivings last night when I compared the slumping schedule that I was using from Spectrum glass, compared to the one in my book from Brenda Griffith. I held fast and went with what I started. My wife and I talked and it was a smaller piece and we could always re-slump it, if needed. Luckily, it was not needed.

So enjoy the pictures, I don't think there is much to add at the moment. My wife is planning to try casting a piece this week, and I will be sure to include information for that as she progresses.

Sunday, May 29, 2011

Full Fuse Test... Successful!, On to Slumping

The results are in! The total firing time for the full fuse for my 6" x 6" piece was 8:15 according to the kiln. It took another 8 and a half hours to get down to approximately room temperature (It actually got down to about 150° and I couldn't take the waiting any longer, so I vented the kiln). I am extremely happy with how this turned out. I really had not done my most terrific job of cutting the glass before testing out the full fuse. Again, impatience. Who me? Couldn't be!

Before I hit the hay last night, I prepared my mold by putting a few coats of kiln wash on it. I let it dry over night so it would be ready, right when I needed it today. The bottom picture is of the plate of glass set in the mold getting ready to fire. It is much smaller than the mold is designed for, but I'm reasonably comfortable that it will work out just fine. I made sure that each side of the plate was the same distance from the top of the mold, to ensure even sides when slumped.

For slumping I am using the following slump schedule:

Before I hit the hay last night, I prepared my mold by putting a few coats of kiln wash on it. I let it dry over night so it would be ready, right when I needed it today. The bottom picture is of the plate of glass set in the mold getting ready to fire. It is much smaller than the mold is designed for, but I'm reasonably comfortable that it will work out just fine. I made sure that each side of the plate was the same distance from the top of the mold, to ensure even sides when slumped.

For slumping I am using the following slump schedule:

| Segment | Ramp | Temp | Hold |

| 1 | 150° | 300° | 15 |

| 2 | 300° | 1235° | 15 |

| 3 | AFAP | 950° | 60 |

| 4 | 150° | 800° | 10 |

Here's to crossing my fingers for now!

Saturday, May 28, 2011

Full Fuse Test 1

If I were a nail biter, I'd be doing it now. I thought that the kiln had some built in schedules for full fuse, tack etc, but I can't seem to find them in the instructions anywhere. It's probably just as good, all considered that I had to enter in my own firing schedule. This way I know exactly what is happening, if I need to make adjustments later. I used a firing schedule that was provided to me during a get to know your kiln class at my local glass shop, The Glass Place, who in turn got it from Spectrum Glass.

The schedule I am using is firing at a rate of 300° per hour, until it reaches 1150°, it will then hold that temperature for 30 minutes. This is so that the whole glass piece evens out to the same temperature before going higher. Next, it will fire at a rate of 400° per hour until it reaches 1475°, and I will hold it there for 10 minutes. Somewhere around 1465° - 1500° is when a full fuse takes place. I'm told it can be different for different types of glass and how many layers of glass you are dealing with at the moment. After the full fuse hold, I will let it cool down as fast as it can to 950° and it will hold that for 60 minutes. This will allow the glass to anneal. It will then ramp down at a rate of 150° and hour to 800° and hold for 10 minutes. To tell the truth, I'm not absolutely sure why they have this step in there. My guess is that it keeps stress out of the glass by letting it cool down slowly. At that point the kiln will turn off and cool at whatever natural rate it will cool to room temperature. This schedule can be written simply as.

I was advised to go ahead and try to make some things while I was testing out Full fusing, slump fusing, tack fusing, and contour fusing. I decided to use some of my scrap glass to make a small dish, for this first attempt. I like the glass in the middle section because it has a nice sparkle in it, that really comes out when fired. I had done a large sushi dish in this same color scheme when I was taking my fusing class way back when, so this is being put to a good use. If it turns out, I may gift it to the same people I gave the other piece to, so they have a sauce dish. Who knows, the whole thing may blow up to!

The schedule I am using is firing at a rate of 300° per hour, until it reaches 1150°, it will then hold that temperature for 30 minutes. This is so that the whole glass piece evens out to the same temperature before going higher. Next, it will fire at a rate of 400° per hour until it reaches 1475°, and I will hold it there for 10 minutes. Somewhere around 1465° - 1500° is when a full fuse takes place. I'm told it can be different for different types of glass and how many layers of glass you are dealing with at the moment. After the full fuse hold, I will let it cool down as fast as it can to 950° and it will hold that for 60 minutes. This will allow the glass to anneal. It will then ramp down at a rate of 150° and hour to 800° and hold for 10 minutes. To tell the truth, I'm not absolutely sure why they have this step in there. My guess is that it keeps stress out of the glass by letting it cool down slowly. At that point the kiln will turn off and cool at whatever natural rate it will cool to room temperature. This schedule can be written simply as.

| Segment | Ramp | Temp | Hold |

| 1 | 300° | 1150° | 30 |

| 2 | 400° | 1475° | 10 |

| 3 | AFAP | 950° | 60 |

| 4 | 150° | 800° | 10 |

I will probably be writing all future schedules in this manner.

I was advised to go ahead and try to make some things while I was testing out Full fusing, slump fusing, tack fusing, and contour fusing. I decided to use some of my scrap glass to make a small dish, for this first attempt. I like the glass in the middle section because it has a nice sparkle in it, that really comes out when fired. I had done a large sushi dish in this same color scheme when I was taking my fusing class way back when, so this is being put to a good use. If it turns out, I may gift it to the same people I gave the other piece to, so they have a sauce dish. Who knows, the whole thing may blow up to!

Saturday, May 14, 2011

Shimmy Shimmy Shake with a side of electricity

The kiln is now set up in the basement, which is unfortunately a little damp at the moment. It is very important that the kiln be level. I've struggled for a while on exactly how to shim the kiln stand before placing the kiln on it. If I used a regular wood shim it may rot over time or possibly collapse over time with a kiln that is approximately 165lbs.. So today I spent some time at Lowe's looking at outlets for the kiln (more on that in a second) and I got inspired. I could use electrical junction box covers as shims! They only cost about $.59 a piece and they could handle the weight and not rot out. I am extremely happy with myself for this thought.

My kiln takes a 20 amp plug, the same that a lot of clothes washers take. Unfortunately for me my outlet for the dryer is too far away for me to also use for the kiln. The kiln really should have its own breaker. Our plan had been to have it on the same breaker as the washer, but never use them at the same time. I also considered trying to make an extension cord for the outlet, but I was strongly advised against it, and I was uncomfortable with my own idea for that in any case. I am having a certified electrician come over tomorrow and look at it for me. It may only cost around $100 - $120 to do it, and considering the safety factor, it is the right thing to do. So alas, I have to wait even longer to prep the kiln and start experimenting.

Till next time.

Friday, May 13, 2011

Kiln Gloves!

Gloves are pretty damed important when it comes to messing with temperatures upwards of 1800°. There are 3 main types types used by kiln users from what I have read. They are welders gloves, Kevlar gloves and Zetex gloves.

Welders gloves will cover your forearms and protect you from very short exposures to the kiln. They would not be used for raking the glass, or bending bracelets or the like. I'm seeing prices from $4 to about $20 currently from a brief search. Looking high and low I cannot seem to find a consistent heat rating for this type of glove. My educated guess would be about 350°.

Kevlar gloves are good for about 800 °and temporarily up to 1,000°. These seem to be going for anywhere between $30 - $50. From what I'm reading this is the most common type used with the kiln. You can use this type to rake the glass or manipulate it.

Finally, you have Zetex gloves. Zetex comes in two flavors, Zetex and Zetex plus. These gloves are rated anywhere from 1,000° up to 2,000° for temporary exposure. They are made out of a treated fiberglass. Prices are ranging upwards of $80 for these gloves.

Personally, I want to be as safe as possible. 3rd degree burns are not my thing. I've gone for a pair of 14" Zetex plus gloves for $60. The rating from the manufacturer says these should be good up to 1800°. This makes me feel pretty safe and I think it is well worth the extra money. A trip to the ER would certainly cost more. I'm all about avoiding that.

Welders gloves will cover your forearms and protect you from very short exposures to the kiln. They would not be used for raking the glass, or bending bracelets or the like. I'm seeing prices from $4 to about $20 currently from a brief search. Looking high and low I cannot seem to find a consistent heat rating for this type of glove. My educated guess would be about 350°.

Kevlar gloves are good for about 800 °and temporarily up to 1,000°. These seem to be going for anywhere between $30 - $50. From what I'm reading this is the most common type used with the kiln. You can use this type to rake the glass or manipulate it.

Finally, you have Zetex gloves. Zetex comes in two flavors, Zetex and Zetex plus. These gloves are rated anywhere from 1,000° up to 2,000° for temporary exposure. They are made out of a treated fiberglass. Prices are ranging upwards of $80 for these gloves.

Personally, I want to be as safe as possible. 3rd degree burns are not my thing. I've gone for a pair of 14" Zetex plus gloves for $60. The rating from the manufacturer says these should be good up to 1800°. This makes me feel pretty safe and I think it is well worth the extra money. A trip to the ER would certainly cost more. I'm all about avoiding that.

Thursday, May 12, 2011

First Mistake, The kiln stand....

Last Night I finally cleaned up enough of the basement to begin putting together the kiln stand. The stand is essential for operating the kiln safely. This stand will keep the kiln approximately 20" off of the ground. The instructions seemed to imply that the stand needed to be weaved together, like you would with a cardboard box that you wanted to close without tape. See picture to the left. I wrote paragon an email asking if this was indeed the case, but they have not replied to me as of yet. Having found the picture on the internet, I'm going to assume that I do need to weave it together, which means taking 2 legs off and weaving correctly and then placing them back. After that I need to make absolutely certain that the shelf is level before putting the kiln on it and having some fun. I'm sure some homemade pictures will be on their way soon.

Update: Paragon emailed back today and confirmed that the kiln stand is to be weaved together.

Monday, May 9, 2011

Kiln is at the house!

So the kiln made it to my house on Saturday, but I was unable to get it set up for now. I've had a lot of cleaning of the basement that had to be accomplished before we place it. I will post more once that is done. But for now, you can check out my glass projects from my Fused glass class I took a couple years ago. I can only advance from here.. I'm still very excited, if moving a bit slowly.

Tuesday, May 3, 2011

The Kiln is in Pittsburgh!

The kiln is here... kind of. It is at the glass studio that I am purchasing it from, but I can't make it there until Saturday to pick it up. Why do I have to work a day job again? Someone please remind me... *Sigh*

There are a couple projects around the house that I must put some time into in order to be ready to do ANYTHING with the kiln.

But, Oh Happy Day! The kiln is almost in my grimy little hands!

There are a couple projects around the house that I must put some time into in order to be ready to do ANYTHING with the kiln.

But, Oh Happy Day! The kiln is almost in my grimy little hands!

Wednesday, April 27, 2011

First book

This is my first book on glass fusing. It seems a decent overview of what all materials you need and the basics on how to do things. The bonus with it is that it has a lot of projects pictures and instructions on how to do them. While I will take and idea and run with it, I always feel its good to do it per instruction at least the first time. Then I can riff on the idea from there and make my own mistakes.

I read a quote yesterday that I just absolutely love attributed to Scott Adams. "Creativity is allowing yourself to make mistakes. Art is knowing which ones to keep."

I read a quote yesterday that I just absolutely love attributed to Scott Adams. "Creativity is allowing yourself to make mistakes. Art is knowing which ones to keep."

Tuesday, April 26, 2011

Why Glass Synchronicity?

Why Glass Synchronicity?

So many things have to happen just perfectly for fused glass to come out great. Everything from the right cuts, fitting and color of glass to the right temperatures and times and whatever else there might be to it. Yes, I have yet to really start fusing. I took a class in fusing 2 years ago and made some items that I had fused for me. However I've never set the times and temps myself or done much experimenting as of yet. I did however just order a paragon-16 kiln. it should be in my waiting hands in the next 2 weeks or so. My intention is to document my learning experience and do some record keeping for myself with this site.

So many things have to happen just perfectly for fused glass to come out great. Everything from the right cuts, fitting and color of glass to the right temperatures and times and whatever else there might be to it. Yes, I have yet to really start fusing. I took a class in fusing 2 years ago and made some items that I had fused for me. However I've never set the times and temps myself or done much experimenting as of yet. I did however just order a paragon-16 kiln. it should be in my waiting hands in the next 2 weeks or so. My intention is to document my learning experience and do some record keeping for myself with this site.

Subscribe to:

Comments (Atom)